- TOP

- ABOUT US

Company

| Company name | Faraday Factory Japan LLC |

|---|---|

| Founded | July 2011 |

| CEO | Sergey Lee |

| info@faradaygroup.com | |

| Head Officer TEL | +81(0)42-649-2325 |

| Business content | R&D, manufacturing and sales of high-temperature superconducting wire (HTS Tape) |

| Address | 【Head Office】 1F, FINE Bldg. 2956-6 Ishikawamachi, Hachioji, Tokyo 192-0032 TEL:+81-42-649-2325 【Zama Factory】 5-12-15Hibarigaoka, Zama, Kanagawa, 252-0003 TEL:+81-3-4335-3000 【R&D Division】 SIC-3, 1880-2 Kamimizo, Chuo-ku, Sagamihara, Kanagawa, 252-0243 |

Greeting

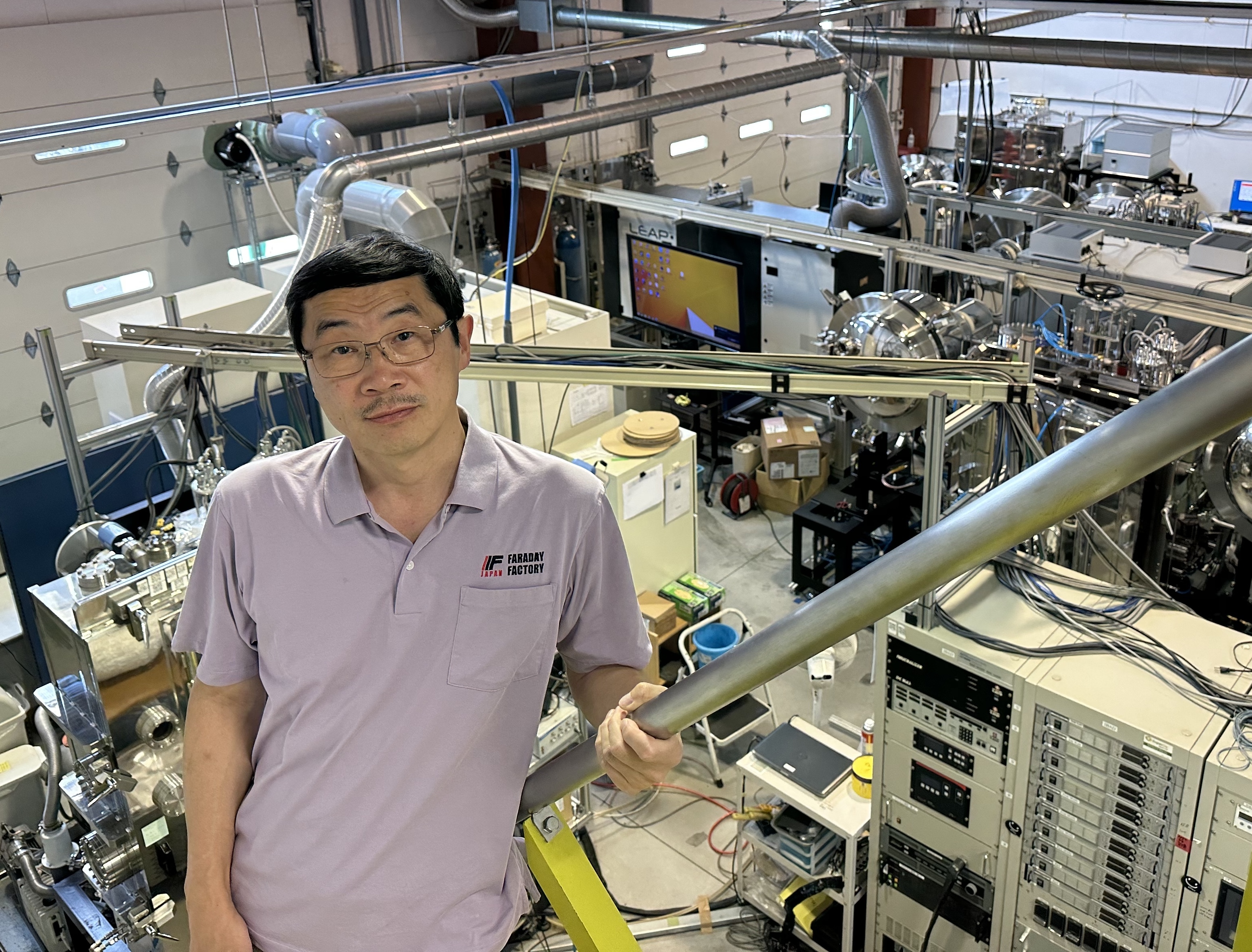

CEO Message

On July 14, 2023, the company celebrated its 12th anniversary. Following Eastern traditions, we can say that a full cycle of its existence has ended. This is a very short period by the standards of human life, let alone a company's lifetime. At the same time, it can be said without exaggeration that this period is critical when it comes to a start-up operating in the field of high technologies, which undoubtedly include high-temperature superconductors in next-generation wires. Most start-ups disappear during this period, and only a few manage to break through and take a leading position in their industry. We can now confidently say that our company is among them. There are various criteria for assessing a company's success in terms of financial performance, sales growth, data from various ratings, and all of them are present to some extent in the evaluation of our company's activities. At the same time, as the head of the company since its foundation, I can see those hidden aspects of it that are the real reasons for success.

First and foremost, I would like to note that the backbone of our company consists of people who have worked together for many years in universities and research centers, who were direct witnesses to the beginning of the "superconducting boom" in the late 80s - early 90s of the 20th Century. We saw the subsequent period of some disappointment when it turned out that the practical use of this phenomenon and materials is associated with incredible difficulties. For those who decided to move on, it was necessary to work under the conditions of reducing state funding and distrust on the part of private investors. I am very grateful that at this moment, fate brought us together with people who believed and invested in our success. Since the foundation to the present day, we have maintained a management style where all key decisions are made as quickly, flexibly, and openly as possible, which is our main competitive advantage.

Alongside experienced employees, in recent years, we have managed to create a young team of managers and engineers. In our recruitment policy, we have chosen to attract foreign workers who have decided to tie their lives with Japan and at this stage they make up about 70% of the company's staff. At the same time, the company has sought to attract a significant number of part-time workers from among the local residents by providing them with a maximally flexible schedule, convenient for students, homemakers with children, retirees. The combination of these approaches has allowed us to solve the problem of "staff shortage", which most starting firms face.

I am very grateful to our suppliers and equipment and materials manufacturers, with most of whom we have long-standing relationships. We operate in a new field where there is no concept of "standard equipment" and almost every device or production unit is highly specialized.

Our special gratitude to our clients who believed in the quality of our product and chose our company to implement their projects. From the moment of foundation until today, we pay special attention to customizing our wire for specific project tasks even if the amount of special wire is small, and its production is sometimes commercially unfeasible.

We are constantly working to improve our equipment and the quality of our product within the approved R&D plan, using the company's internal resources. The company's participation in national projects like NEDO allows us to conduct research and development with a longer-term perspective, and we highly appreciate such support from the Japanese government.

I have no doubt that the superconductor market is expecting a new boom in the near future, as there are no other real alternatives to these materials. The level of technology development, the parameters of superconducting materials, and their price have closely approached the values at which new multi-billion-dollar markets will open. The societal demand for renewable energy sources, minimization of carbon dioxide emissions, and the green agenda also leaves no doubt that the demand for new-generation superconductors will increase significantly.

Evaluating the company's prospects and plans for the new stage of development, I can say that one of the main tasks is to maintain the leading position that has been achieved over the past years. Thinking about this, I always remember the phrase that our scientific supervisor (under whose guidance almost all key employees of the company worked) liked to repeat from Lewis Carroll's story about Alice in Wonderland: "Here we must run as fast as we can, just to stay in place. And if you wish to go anywhere, you must run twice as fast as that." We certainly do not want to stay in place, even if it is a leader's place, we will run even faster….

Best regards,

Sergey Lee, CEO Faraday Factory Japan LLC

Sergey Lee, CEO Faraday Factory Japan LLC

Investor Relations

New technologies are the backbone of the energy transition to a zero-carbon economy. High temperature superconductors enable the most disruptive of them (compact fusion, electrical aviation) and make other efforts cheaper (like low loss transmission and lightweight wind generators). The small production and high cost of HTS used to be a showstopper, but now it is about to change. The HTS price went down by a factor of 2 in 5 years. The next 5 years will see HTS becoming cheaper than copper. Building upon our vast practical experience, we have drafted a robust plan to build the world's largest factory for the production of state-of-the-art HTS tapes. As demand continues to exponentially unfold, Faraday Factory Japan will become a model to copy-paste, eventually leading to a billion-sized market by 2030.

Locations

Head Office

TEL:+81-42-649-2325

Zama Factory

TEL: +81-3-4335-3000